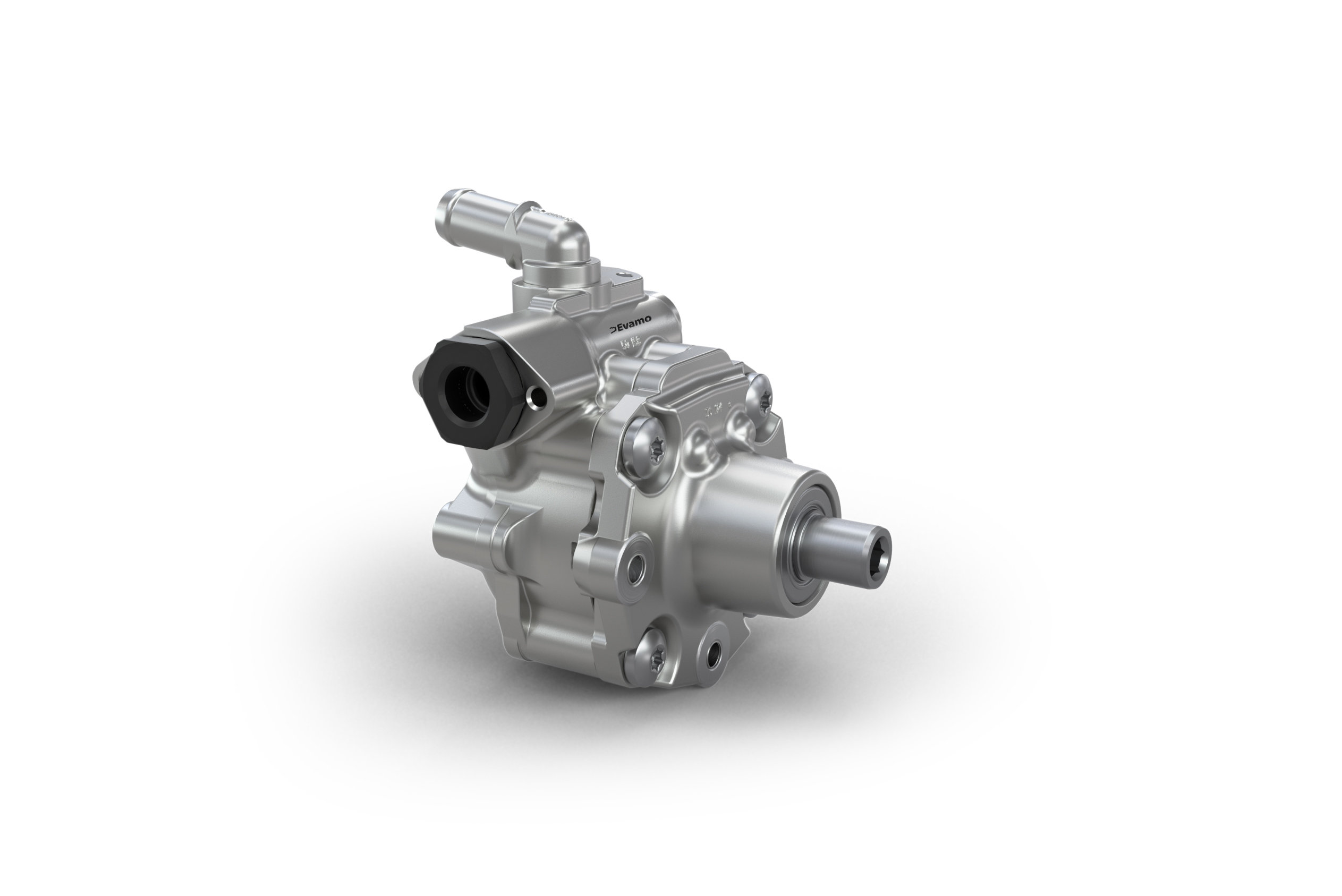

The energy- and fuel-saving Varioserv® power steering pump supplies exactly the right amount of oil that is needed for operating hydraulic steering systems in passenger cars and light commercial vehicles.

Function

Variable displacement pump with reduced energy expenditure

The Varioserv® power steering pump is powered via a motor belt drive. The hub or belt pulley is pressed onto the shaft. Mounting the pump to the engine bracket is done either directly or via a pump bracket.

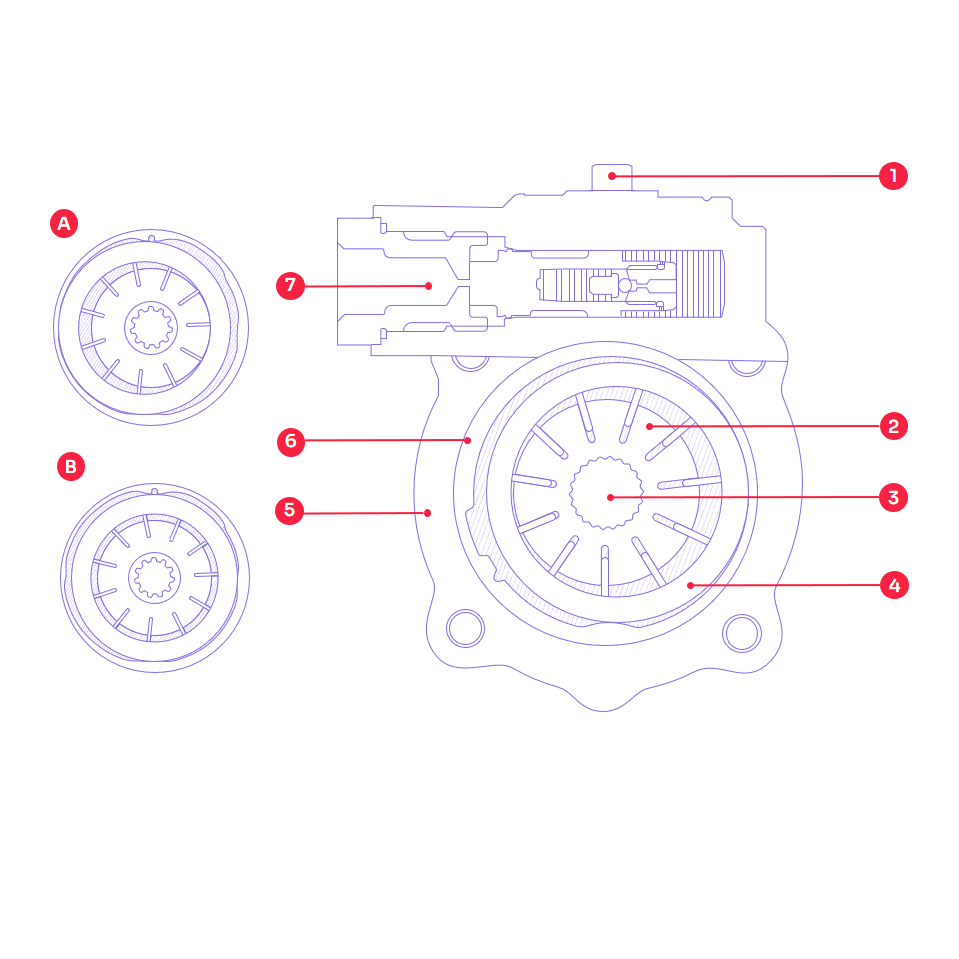

The Varioserv® power steering pump consists of a housing with a pressed-in intake port as well as an integrated volume flow control, valve screw with a pressure connection thread, cover, front plate, shaft and rotor set. The rotor set is comprised of the outer ring, rotor, eleven radially-guided blades and the cam ring. The pump shaft is installed in the housing and in the cover with plain bearings.

Contrary to the double-stroke rotor set of standard vane pumps, the cam ring in the single-stroke Varioserv® is adjustable and generates an adjustable geometric delivery volume via the varying eccentricity.

The cam ring adjustment is speed-dependent. This only results in the decreasing pump space generating a reduced geometric delivery volume. At higher speeds, the reduced power consumption leads to significantly lower energy consumption, whereby fewer cooling measures are required in the steering system.

The volume flow control limits the supplied volume flow to a fixed value and a pressure control valve in the valve pistons controls the system pressure.