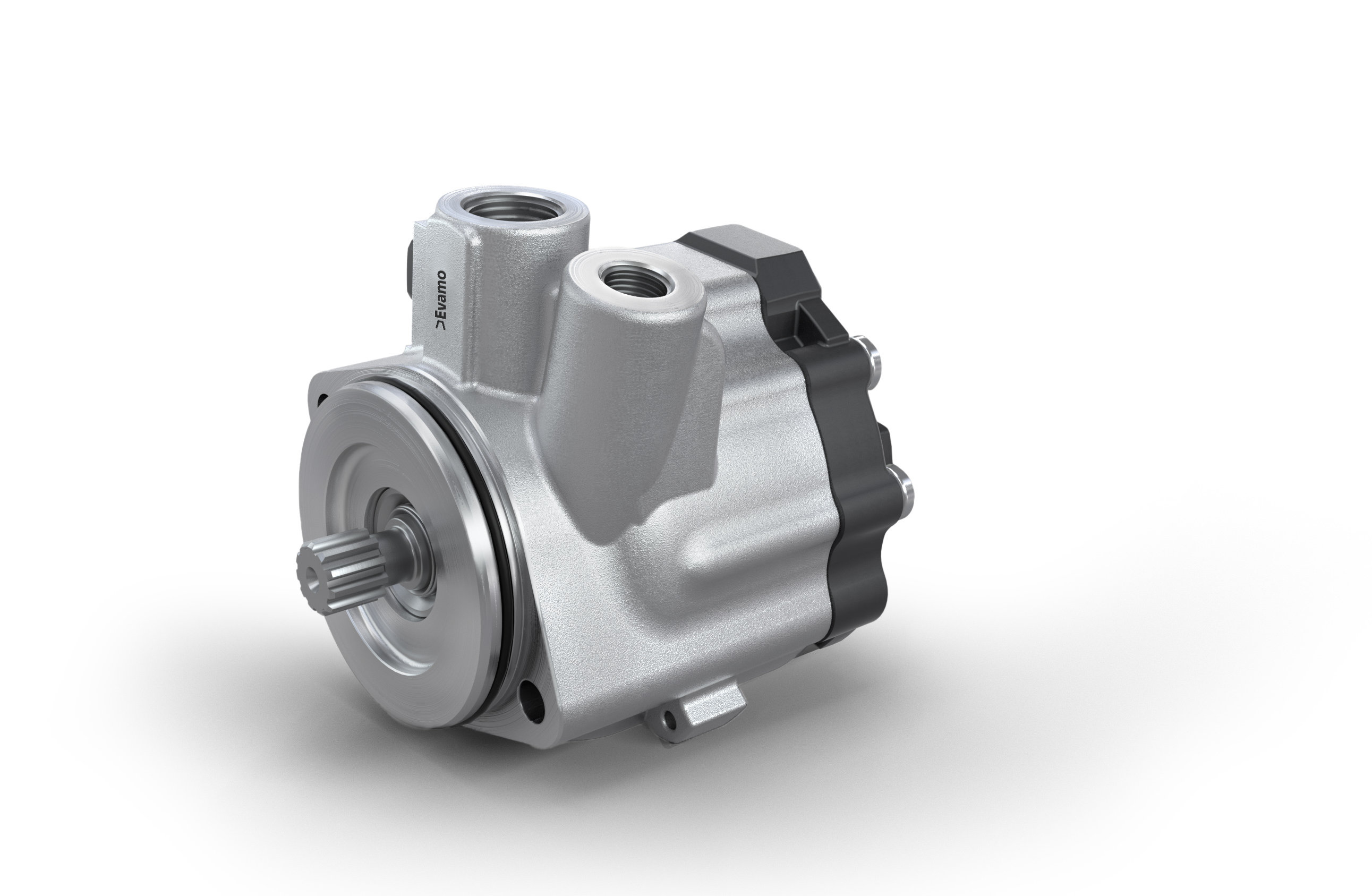

The Varioserv® power steering pump supplies exactly the right amount of oil that is needed for operating hydraulic steering systems in commercial vehicles.

Function

Energy-saving variable displacement pump for hydraulic steering systems

The Varioserv® power steering pump is designed for connection to the air compressor or a power take-off on the engine. The shaft connects by means of a cross-slotted disk or spline toothing.

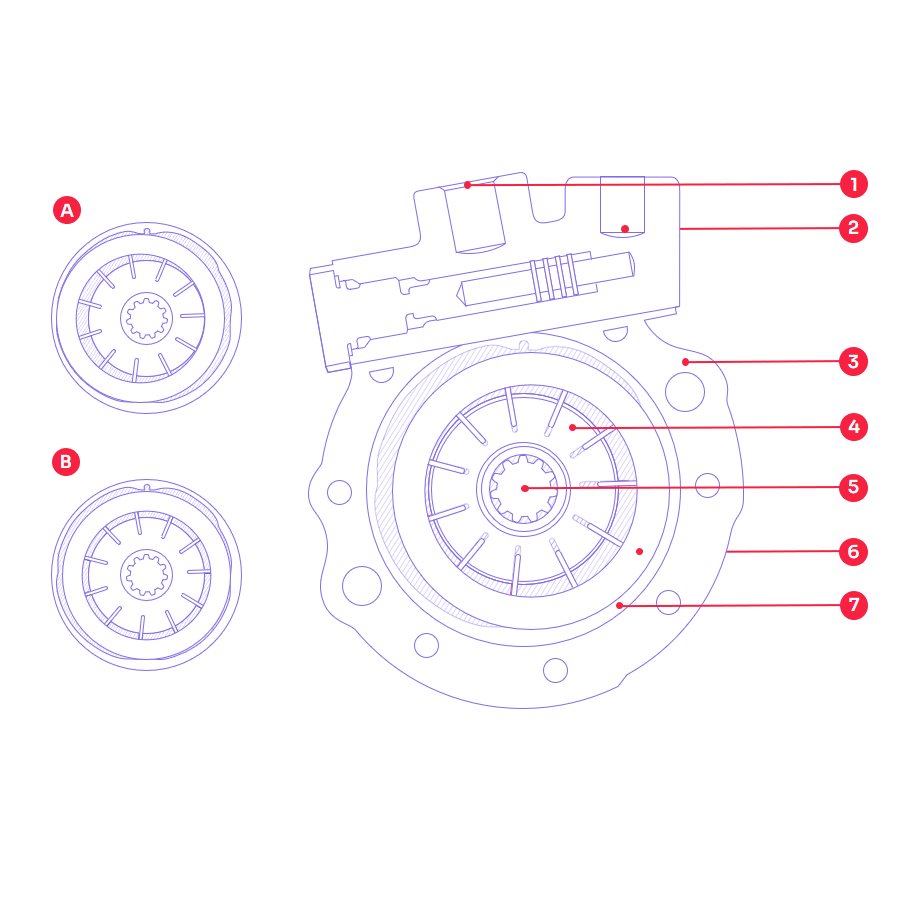

The Varioserv® power steering pump consists of a housing with an integrated control valve, cover, front plate, shaft and a rotor set. The rotor set is comprised of the rotor, eleven radially-guided blades as well as an eccentrically-mounted and hydraulically-adjustable cam ring and an outer ring.

Up to a defined control point, the Varioserv® behaves like a conventional power steering pump. As soon as this control point is reached, the geometric delivery volume is reduced by the cam ring adjustment according to the defined volume flow.

The volume flow is regulated depending on the engine speed and the pressure requirement. This lower delivery volume compared to a conventional power steering pump leads to decreased power consumption and thus a lower system temperature.

| Size | 7654 | 7655 | 7656 | |

| Displacement volume (cm³/rev) | 22 | 25 | 28 | |

| Max. rotational speed (rpm) | 5,000 | |||

| Max. pressure (bar) | 185 | |||

| Controlled volumetric flow (dm³/min) | 16-25 | |||

| Suction port | 1 1/16“ – 12UN 2B | |||

| Thread (suction port) | M26 x 1.5 | |||

| Pressure port | 3/4“ – 16UNF 2B | |||

| Thread (pressure port) | M18 x 1.5 | |||

| Drive direction of rotation | clockwise or counter-clockwise | |||